Why 3D Printing is Transforming Architecture and is Killing You

Imagine presenting your next architectural vision not just with flat renderings, but with a tangible, intricate model that clients can see, touch, and truly understand. For many architects, this was once a time-consuming, expensive dream. Today, it's an accessible reality

"66% higher conversions than those earned by 2D solutions."

https://www.threekit.com/21-3d-configurator-ecommerce-statistics-2022

In the rapidly evolving world of architecture, innovation is key to staying ahead of the curve. Enter 3D printing technology that is redefining how architectural models and concepts are conceived, designed, and brought to life.

Gone are the days of relying solely on traditional sketching and physical model-making; 3D printing offers unparalleled precision and versatility, allowing architects to visualise their ideas with astonishing clarity.

This transformative tool not only enhances creativity but also significantly shortens project timelines and reduces costs.

As we delve into the impact of 3D printing on architectural design, we’ll explore how this technology is shaping the future of our built environment and empowering architects to push the boundaries of imagination.

Advantages of 3D Printing for Architectural Design

From intricate details to large-scale structures, the possibilities are limitless, paving the way for a new era in architectural innovation. Join us on this journey to discover how 3D printing is not just a trend, but a fundamental shift in the design landscape.

The advent of 3D printing has brought about a seismic shift in the world of architectural modelling. This innovative technology allows for the creation of highly detailed, accurate models directly from digital designs, bypassing the need for manual construction.

By using various materials, including plastics, resins, and even metals, 3D printing offers unparalleled versatility and precision.

Architects can now produce complex geometries and intricate details that would be nearly impossible to achieve with traditional methods.

This evolution is not only transforming the way models are made but also how architects approach the design process itself.

Table of Contents

1. This precision allows architects to explore intricate design elements and experiment with innovative concepts, pushing the boundaries of what is possible in architecture. Additionally, 3D printing can replicate textures and surfaces with remarkable fidelity, providing a more realistic representation of the final structure.

2. Speed is another crucial benefit of 3D printing in architecture. Conventional model-making can be a slow and laborious process, often taking weeks or even months to complete. In contrast, 3D printing can produce models in a matter of hours or days, significantly shortening project timelines. This rapid turnaround enables architects to iterate quickly, testing and refining their designs with greater efficiency. As a result, projects can progress more swiftly from concept to completion, allowing for more dynamic and responsive design processes.

3. Cost savings are also a significant advantage of 3D printing in architectural design. Traditional model-making requires skilled labour and expensive materials, which can add up to substantial costs. 3D printing, on the other hand, can reduce these expenses by automating the production process and utilising more affordable materials. Furthermore, the ability to create precise models with minimal waste contributes to overall cost efficiency. These savings can be particularly beneficial for smaller firms or projects with limited budgets, enabling them to achieve high-quality results without breaking the bank.

Quick Links

Successful Use of 3D Printing in Architecture

One notable example of 3D printing's success in architecture is the creation of the Elbphilharmonie concert hall in Hamburg, Germany. The architects at Herzog & de Meuron utilised 3D printing to produce highly detailed models of the building's complex geometry, allowing them to refine their design and communicate their vision to stakeholders.

The precision and versatility of 3D printing enabled the team to explore innovative concepts and push the boundaries of architectural design, ultimately resulting in a stunning and iconic structure.

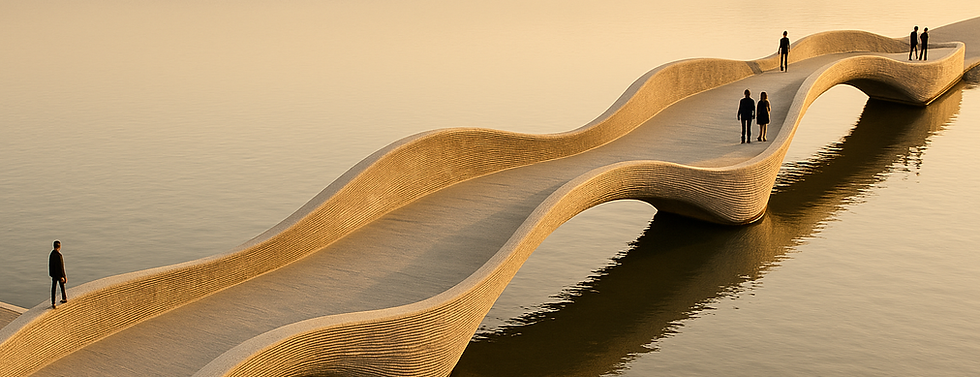

Another case study highlighting the impact of 3D printing in architecture is the construction of a 3D-printed bridge in Madrid, Spain. Designed by the Institute of Advanced Architecture of Catalonia (IAAC), this pedestrian bridge was created using a large-scale 3D printer and a specially formulated concrete mixture.

The technology allowed the designers to achieve complex shapes and intricate details that would have been challenging with traditional construction methods. The success of this project demonstrates the potential of 3D printing to revolutionise not only architectural models but also the construction of full-scale structures.

The use of 3D printing in the renovation of the Notre Dame Cathedral in Paris is another compelling case study. Following the devastating fire in 2019, architects and historians turned to 3D printing to create accurate models of the damaged areas, aiding in the restoration process.

These detailed representations allowed the team to assess the extent of the damage and develop precise plans for rebuilding.

The precision and speed of 3D printing proved invaluable in this critical project, showcasing its potential to support complex and sensitive architectural endeavours.

Who we have Teamed up With

Comparing Traditional Model Making and 3D Printing

When comparing traditional model-making methods with 3D printing, one of the most apparent differences is the level of detail and accuracy achievable.

Traditional techniques often involve manual cutting, shaping, and assembly, which can introduce imperfections and inconsistencies. In contrast, 3D printing relies on digital designs and automated processes, ensuring that every element is produced with exact precision.

This accuracy is particularly valuable for complex geometries and intricate details, which can be challenging to replicate by hand.

The speed of production is another key distinction between traditional model-making and 3D printing. Conventional methods can be time-consuming, with artisans spending weeks or even months to complete a single model.

This extended timeline can delay project progress and limit opportunities for iteration and refinement. Conversely, 3D printing can produce models in a fraction of the time, allowing architects to test and tweak their designs more rapidly.

Imagine turning your digital ideas into actual objects you can touch and hold.

This efficiency can lead to more dynamic and responsive design processes, ultimately resulting in better outcomes.

Cost is a further area where 3D printing offers significant advantages over traditional model-making. The manual labor and specialised materials required for conventional techniques can be expensive, particularly for complex or large-scale models.

3D printing, however, can reduce these costs by automating the production process and utilising more affordable materials. Additionally, the precision of 3D printing minimises waste, further contributing to cost savings.

These financial benefits can be especially valuable for smaller firms or projects with limited budgets, enabling them to achieve high-quality results without incurring prohibitive expenses.

The Role of 3D Printing in Sustainable Design

Sustainability is becoming an increasingly important consideration in architecture, and 3D printing is playing a pivotal role in advancing eco-friendly design practices. One of the key benefits of 3D printing is its ability to minimize waste.

Traditional model-making and construction methods often produce significant amounts of scrap material, which can contribute to environmental degradation. In contrast, 3D printing utilizes additive manufacturing techniques, building models layer by layer with precise control over material usage.

This approach reduces waste and promotes more efficient resource utilisation.

The versatility of 3D printing also supports sustainable design by enabling the use of environmentally friendly materials.

Architects can experiment with biodegradable plastics, recycled resins, and other sustainable materials, incorporating them into their models and structures. This flexibility allows for the exploration of innovative solutions that prioritize environmental responsibility.

Additionally, 3D printing can facilitate the creation of components that are optimized for energy efficiency, contributing to the development of greener buildings.

Furthermore, 3D printing can enhance the sustainability of architectural design by enabling more precise and efficient construction processes. Traditional construction methods often involve significant energy consumption and material waste, especially when dealing with complex geometries or intricate details.

By utilising 3D printing, architects can produce components that fit together seamlessly, reducing the need for additional modifications and minimising resource expenditure. This efficiency not only supports sustainable design but also contributes to cost savings and improved project timelines.

Future Trends in 3D Printing for Architectural Applications

As 3D printing technology continues to evolve, several exciting trends are emerging that promise to further revolutionise architectural design. One such trend is the development of advanced materials specifically tailored for 3D printing.

Researchers are exploring new formulations that combine strength, durability, and aesthetic appeal, expanding the range of applications for printed components.

These innovations could enable the creation of more complex and durable structures, pushing the boundaries of architectural design.

Another promising trend is the integration of 3D printing with other digital technologies. Combining 3D printing with virtual reality (VR) and augmented reality (AR) can enhance the design process by allowing architects to visualise and interact with their models in immersive environments.

.png)

This integration can facilitate more intuitive and collaborative design workflows, enabling architects to explore innovative concepts and refine their ideas with greater precision.

Additionally, advancements in artificial intelligence (AI) and machine learning could further optimize 3D printing processes, enhancing efficiency and accuracy.

The development of large-scale 3D printers is also a significant trend shaping the future of architectural applications. These printers are capable of producing larger and more complex components, overcoming some of the scalability challenges currently facing the technology.

With the advent of these machines, architects could create full-scale structures using 3D printing, transforming the construction industry. This capability could lead to more efficient and sustainable building practices, ultimately paving the way for a new era in architecture.

FAQs

Imagine turning your digital ideas into actual objects you can touch and hold.

Imagine turning your digital ideas into actual objects you can touch and hold.

Imagine turning your digital ideas into actual objects you can touch and hold.

Imagine turning your digital ideas into actual objects you can touch and hold.

Imagine turning your digital ideas into actual objects you can touch and hold.

Imagine turning your digital ideas into actual objects you can touch and hold.

How Architects Can Get Started with 3D Printing

Architectural 3D printing affords an extraordinary range of applications that span the entire project lifecycle and elevate every facet of design and delivery.

Beginning at RIBA Stage 0–1 (Strategic Definition & Preparation), architects can quickly realise competition models and early massing studies: simple form-block prints in PLA or resin that convey volumetric concepts, shadow studies, and daylight analyses.

These rapid, low-cost prints accelerate client feedback and enable more iterations before committing to refined drawings.

Moving into Stage 2–3 (Concept & Developed Design), planning and context architectural models become indispensable. By importing GIS terrain data and site surveys, 3D-printed topography and surrounding streetscapes provide local authorities and stakeholders with tangible site context.

Layered colour coding printed or applied post-process can highlight land use zones, pedestrian routes, and green spaces, making planning applications clearer and more persuasive.

At Stage 4 (Technical Design), architects exploit 3D printing architecture to fabricate detailed façade prototypes, bespoke connector plugs, and parametric panel studies.

Powder-bed fusion processes (SLS/MJF) deliver high-resolution nylon panels to test interlocking systems, cladding strategies, and daylight control devices.

Flexible TPU prints simulate gasket behaviour, while resin prints reveal crisp panel textures ensuring design for manufacture and assembly (DfMA) considerations are validated long before construction.

During Stage 5–6 (Construction & Handover), marketing suite models and immersive visualisation environments come to life.

Fully coloured PolyJet or binder-jet models showcase key selling features floorplans, amenity spaces, roof terraces—allowing prospective buyers to explore snap-fit building sections and interactive components.

Likewise, architects can create VR-ready modular assemblies: printed pieces that slot together to form tactile display walls or augmented-reality markers for on-site app integration.

Finally, in Stage 7 (Use & Maintenance), 3D printing offers pragmatic site aids, spare part fabrication, and custom jigs. Need a bespoke bracket for a unique façade clip?

Print it overnight on a UK 3D printing service.

Require a temporary formwork insert for in-situ concrete? TPU or ABS inserts expedite on-site adjustments without costly steel tooling.

Throughout, whether working with in-office FDM machines for quick form-studies or partnering with specialist bureaus for high-fidelity 3d printed architectural models, architects can harness 3d printing architecture to streamline workflows, reduce waste, engage clients, and push creative boundaries all while keeping budgets on track and timelines tight.